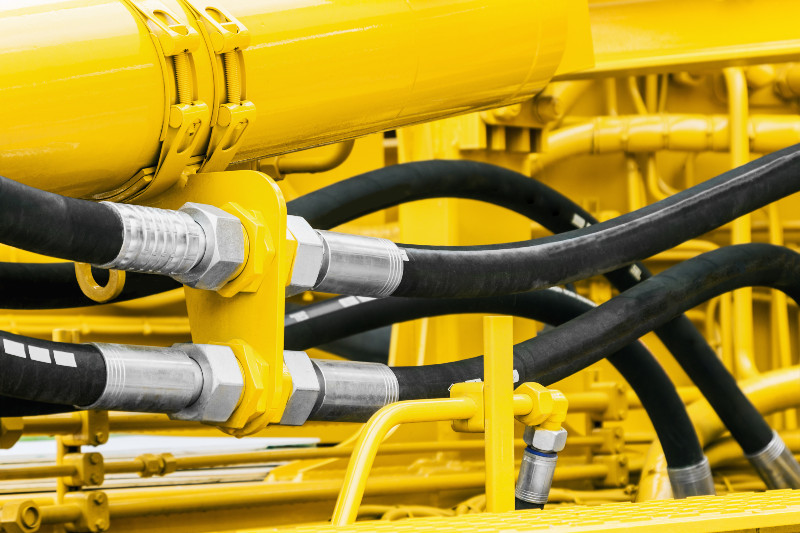

Industrial operations depend on reliable, efficient piping systems to transport fluids and gases under varying pressures and temperatures. Achieving leak-free connections is a top priority, especially in sectors such as chemical processing, oil and gas, food and beverage, and pharmaceuticals. For professionals searching for robust solutions that minimize downtime and safety risks, Stainless Steel Tube Fittings are a trusted choice for ensuring secure, leak-free connections in even the most demanding environments.

The Importance of Leak-Free Connections

Leaks in industrial piping systems can lead to a host of issues, including product loss, contamination, equipment damage, and hazardous working conditions. The cost of addressing leaks—whether through repairs, lost production time, or safety incidents—can be substantial. That’s why selecting the right tube fittings is crucial for maintaining system integrity and meeting compliance standards.

Why Stainless Steel?

Stainless steel stands out for its exceptional durability, resistance to corrosion, and ability to withstand high pressures and temperatures. These properties make it ideal for use in harsh industrial settings where lesser materials might fail or degrade over time. Additionally, stainless steel is non-reactive, ensuring compatibility with a wide range of chemicals and fluids.

Key Advantages of Stainless Steel Tube Fittings

- Corrosion Resistance: Stainless steel’s unique alloy composition resists rust and chemical attack, even when exposed to aggressive media or extreme environmental conditions.

- Strength and Reliability: The material maintains its structural integrity under high-pressure scenarios, reducing the risk of deformation or failure.

- Longevity: Stainless steel fittings often outlast those made from other materials, lowering maintenance costs and replacement frequency.

- Sanitary Properties: For industries like food and beverage or pharmaceuticals, stainless steel provides a clean, non-porous surface that resists bacteria and contamination.

How Stainless Steel Tube Fittings Prevent Leaks

The design and engineering of tube fittings play a significant role in ensuring leak-free performance. Stainless steel fittings employ advanced sealing technologies and precision manufacturing to guarantee a tight, secure fit. Here’s how they deliver leak-free connections:

- Precision Machining: High-quality fittings are manufactured to exacting tolerances, ensuring a perfect match between the tube and fitting components. This minimizes gaps that could allow leaks.

- Compression Sealing: Many stainless steel fittings use a compression mechanism that creates a strong mechanical seal as the nut is tightened. This seal remains intact even under vibration or thermal cycling.

- Double Ferrule Systems: Some fittings incorporate dual ferrules—one to grip the tube and another to create a leak-proof seal—offering additional security in high-stress applications.

- Consistent Material Quality: Stainless steel’s uniform composition ensures predictable performance, even when exposed to corrosive or high-temperature environments.

Best Practices for Leak-Free Installation

While the quality of the fitting is crucial, proper installation also plays a pivotal role in achieving leak-free connections. Consider these best practices:

- Follow Manufacturer Guidelines: Always consult and adhere to the recommended torque values and assembly procedures.

- Use Compatible Tubing: Ensure the tubing material and dimensions match the fitting specifications.

- Inspect Components: Check for defects, burrs, or contamination before installation.

- Regular Maintenance: Periodically inspect connections to detect wear or loosening due to vibration or thermal cycling.

Delivering Reliable Performance in Demanding Applications

Stainless steel tube fittings are engineered to meet the rigorous demands of modern industrial systems. Their superior strength, corrosion resistance, and advanced sealing technologies make them a reliable choice for ensuring leak-free connections across a wide range of applications. By combining high-quality materials with precision engineering and proper installation, industries can achieve greater operational efficiency, reduce maintenance costs, and maintain a safe working environment. Whether you’re upgrading an existing system or designing a new one, investing in the right tube fittings is essential for long-term performance and peace of mind.